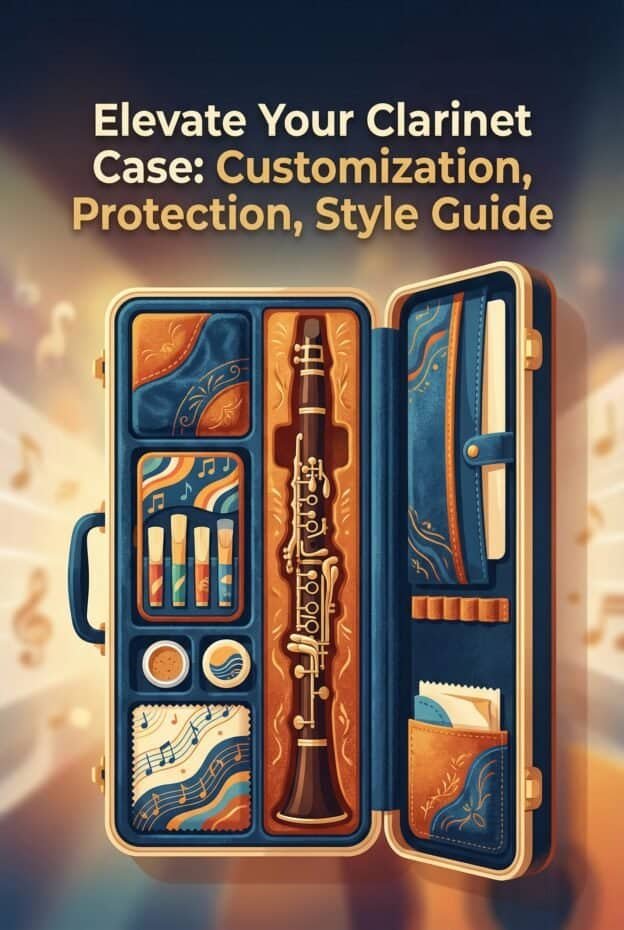

7-step quick guide: Measure your case, choose shock-absorbing foam (EVA or high-density polyethylene), add custom-fit foam inserts for each joint, create pockets for reeds and mouthpiece, line with durable fabric (marine-grade carpet or velour), add moisture control (silica gel plus hygrometer), and finish with straps or clips for accessories.

Why Customize Your Clarinet Case Interior? Benefits for Protection, Organization, and Style

Clarinet case interior customization means reshaping and upgrading the inside of your case so it fits your instrument and accessories perfectly. Done well, it reduces shock, controls humidity, speeds up setup, and reflects your personal style. It is one of the most cost-effective upgrades a serious clarinetist or shop can make.

Most stock cases are built for average instruments and generic accessory layouts. Your clarinet, mouthpieces, ligatures, and reed systems are probably not average. Custom interiors let you protect specific weak points, such as bridge keys and tenons, and keep delicate items like reeds from rattling or cracking during transport.

Organization is another major benefit. Dedicated slots for reeds, swabs, screwdrivers, and backup mouthpieces prevent clutter and lost items. A clear layout also supports faster setup and teardown during rehearsals, pit work, and quick changeovers between ensembles or teaching sessions.

Style matters too. Thoughtful fabric choices, color accents, and clean foam work create a professional impression when you open your case in a lesson, audition, or pit. For teachers and repair shops, a well-organized interior communicates care, expertise, and attention to detail to students and clients.

A Brief History of Clarinet Cases and Martin Freres' Role (History & Legacy)

Early clarinet cases in the 19th century were simple wooden boxes with felt or wool linings. Makers in Paris, Berlin, and Vienna often supplied basic interiors with loose compartments, relying on cloth wraps to protect the clarinet. There was little attention to shock absorption or humidity control beyond simple padding.

By the late 19th and early 20th centuries, catalogs from firms in France and Germany show more shaped interiors. Clarinet joints began to rest in carved wooden cradles covered in velvet or baize. These interiors looked elegant but still transmitted impact directly through rigid wood, which was not ideal for fragile keywork.

Martin Freres, active from the mid-19th century into the 20th century, sold clarinets with cases that reflected changing tastes. Archival examples from circa 1900 to 1930 show plush interiors with deep red or green velvet, fitted recesses for barrels and mouthpieces, and small covered boxes for reeds and grease. These cases balanced display value with basic protection.

As molded plastics and plywood cases spread after World War II, interiors shifted from carved wood to foam and pressed forms. By the 1970s and 1980s, many clarinetists used lightweight cases with expanded polystyrene or polyurethane foam cores, wrapped in velour. Protection improved, but customization remained rare outside high-end touring cases.

Today, professional players and repair shops often modify or replace stock interiors with CNC-cut foam, modular dividers, and humidity control. This evolution from decorative wooden boxes to engineered interiors mirrors the clarinet's shift from salon instrument to global orchestral and band mainstay.

Understanding Clarinet Anatomy: What Parts Need Protection and Why

Effective clarinet case interior customization starts with anatomy. A standard B-flat clarinet has five main parts: mouthpiece with ligature and cap, barrel, upper joint, lower joint, and bell. Each part has specific vulnerabilities that should guide how you design padding, clearances, and support points inside the case.

The mouthpiece and ligature are vulnerable to tip chips and bent screws. They need a snug, soft-lined compartment that prevents side-to-side movement and keeps metal ligatures from pressing against hard surfaces. A separate slot for the cap avoids pressure on the reed or mouthpiece tip during transport.

The barrel is relatively sturdy but can crack if squeezed across the grain or if tenons are stressed. It should sit in a cradle that supports its full length, not just the tenon rings. Avoid any foam or block that presses on the thin socket edges where cracks often start on wooden barrels.

The upper joint carries the most delicate keywork, including the bridge key, trill keys, and register key. It needs support under the body tube, with clearance around keys and posts. The bridge key area must never touch the case wall or lid. Aim for at least 3 to 4 mm of clearance around protruding keys.

The lower joint has long rods and the lower half of the bridge mechanism. It should rest on padded supports that contact the wood between tone holes, not on keywork. The bell is strong but can crack at the socket or chip at the rim if it hits a hard edge, so a padded recess that supports the socket and rim evenly is ideal.

Imagine a simple diagram: a top-down view of your case with outlines of each clarinet part. Mark red zones where keys or posts stick out, and green zones where the wood body can safely touch foam. Then mark arrows showing lid pressure points. This sketch helps you design foam heights and cutouts that avoid stress on keywork.

Best Materials for Case Interiors: Foam, Fabrics, and Fittings (Spec Recommendations)

Choosing the right materials is the foundation of a safe, durable customized interior. You want a balance of shock absorption, long-term stability, low off-gassing, and a surface that will not scratch metal or wood. For most clarinetists, a layered approach with foam, fabric, and hardware works best.

For core padding, EVA foam and high-density polyethylene (HDPE) foam are excellent. EVA in the 45 to 70 kg/m³ density range absorbs shocks and can be cut cleanly. HDPE foam around 2 to 4 lb/ft³ offers firm support for structural blocks. Avoid cheap open-cell upholstery foam for structural cradles because it compresses and degrades quickly.

For top comfort layers, a thin sheet of closed-cell cross-linked polyethylene (XLPE) or neoprene, 3 to 6 mm thick, gives a smooth, slightly softer contact surface. This layer helps distribute pressure and prevents hard impressions from forming in the main foam over time.

Fabric choice affects both durability and moisture behavior. Marine-grade carpet and automotive trunk liner are tough, resist fraying, and handle humidity well. Velour or velvet looks luxurious and is gentle on silver and nickel plating, but it should be bonded well to avoid wrinkles that can press on keys.

For adhesives, use contact cement or spray adhesive rated for foam and fabric, with low VOCs once cured. Test a small piece first to ensure it does not melt the foam or leave a sticky surface. Hot glue can work for small fittings but is less reliable for large surfaces or in hot car interiors.

Fittings like straps, clips, and hardware should be low-profile and non-abrasive. Elastic straps with soft backing, plastic side-release buckles, and nylon webbing are common choices. Avoid bare metal edges inside the case. If you add metal D-rings or snaps, cover contact points with fabric or rubber sleeves.

Step-by-Step DIY: How to Customize Your Case Interior (Measurements, Templates, Tools)

DIY clarinet case interior customization is achievable for careful players and small shops. The key is methodical planning and accurate cutting. Before you start, decide whether you will replace the entire interior or build modular inserts that drop into the existing shell or tray.

Gather tools and supplies: a metric ruler, flexible tape measure, calipers if available, craft knife or snap-off blade, fine-tooth saw for thick foam, cutting mat, marker, masking tape, EVA or HDPE foam sheets, top-layer foam, chosen fabric, spray or contact adhesive, and optional elastic straps or Velcro.

Step 1: Measure your case interior. Record length, width, and depth at several points, including lid depth. Note any hinges, latches, or internal ribs. Sketch a scale drawing. Measure each clarinet part's length and diameter, plus key protrusions. Write down clearances you want around each piece.

Step 2: Create paper or cardboard templates. Trace each clarinet joint on paper with a pencil held vertically, then add 2 to 3 mm around the outline for clearance. Mark key clusters and bridge keys. Cut these templates and test them in the empty case to refine placement and spacing.

Step 3: Transfer templates to foam. Lay templates on the foam sheet, trace with a fine marker, and plan for grain direction if the foam has any. Keep at least 10 mm of foam between adjacent cutouts to maintain strength. Double check that lid padding will meet the joints without pressing on keys.

Step 4: Cut foam carefully. Use a sharp knife and multiple light passes rather than one deep cut. For deep recesses, cut in layers, testing fit with the actual clarinet parts as you go. Slightly bevel the top edges of recesses so parts slide in easily without catching.

Step 5: Test fit everything dry. Place the foam in the case without glue. Insert each clarinet part, mouthpiece, and accessory. Close the lid gently and check for resistance. If you feel pressure, mark contact spots with masking tape and adjust foam height or shape.

Step 6: Add fabric. Cut fabric slightly larger than each foam piece. Apply adhesive to foam and fabric according to instructions, then smooth the fabric from center outward to avoid wrinkles. Cut small relief slits in the fabric at corners and inside curves so it lays flat in recesses.

Step 7: Glue foam into the case. Once fabric is bonded and dry, apply adhesive to the case shell and the back of the foam. Press into place and weight gently until cured. Finally, add straps, clips, or Velcro where needed to secure joints or accessories that might shift.

Organization Systems: Inserts, Pockets, and Modular Dividers for Reeds and Accessories

Custom organization systems transform a cluttered clarinet case into a fast, reliable workspace. The goal is to give every item a home so you can see at a glance what is missing before you leave a rehearsal or gig. Start by listing your daily accessories and ranking them by frequency of use.

Common items include reed cases, spare reeds, mouthpieces, ligatures, caps, cork grease, swabs, cleaning cloths, screwdrivers, and small tools. High-use items like reeds and swabs should sit near the opening edge of the case for quick access. Rarely used items can live in deeper or covered compartments.

Foam inserts with cutouts for reed cases and mouthpieces work well. Design recesses that fit the outer dimensions of your reed case or mouthpiece box, not individual reeds. This way, you can swap brands or cases without re-cutting foam. For loose reeds, consider a small covered tray or a commercial reed case stored in a dedicated slot.

Fabric or mesh pockets attached to the lid are useful for flat items like swabs and cloths. Use low-profile pockets so they do not press on the clarinet when the lid closes. Elastic-top mesh pockets let you see contents quickly and prevent small items from sliding around or falling out.

Modular dividers are ideal for players who change setups often. You can create a grid of shallow foam blocks with Velcro on the bottom, then line the case floor with the matching Velcro loop fabric. This lets you rearrange compartments for different ensembles, travel needs, or teaching days.

For repair shops and teachers, label compartments subtly with fabric tags or small printed labels. Mark areas for student instruments, loaner mouthpieces, and repair tools. A labeled, modular interior reduces confusion during busy days and helps assistants or students return items correctly.

Climate & Moisture Control: Hygrometers, Desiccants, and Insulation Tips

Humidity control is critical for wooden clarinets and cane reeds. A customized case interior gives you space to integrate hygrometers, desiccants, and insulation features that stabilize the microclimate around your instrument. This can reduce cracking risk and extend reed life significantly.

Start by adding a small digital hygrometer inside the case. Place it where it is visible when you open the lid but not pressing on the clarinet. Aim to keep relative humidity between about 40 and 60 percent for most grenadilla clarinets, adjusting for your local climate and maker recommendations.

Silica gel packets are common desiccants. Use rechargeable or color-indicating types so you know when to dry them out. Place them in a ventilated pocket or small perforated container inside the case, away from direct contact with wood surfaces to avoid localized over-drying.

In very dry climates, a two-way humidity control pack designed for wood instruments can help maintain a stable range instead of only drying. Create a dedicated, ventilated compartment or pouch for these packs so they do not touch pads or metal directly. Monitor your hygrometer closely when you first add them.

Insulation also matters. A slightly thicker foam layer in the lid and base slows temperature swings when you move between air conditioning and outdoor heat or cold. Avoid sealing the case so tightly that moisture cannot escape at all. A balance between insulation and gentle air exchange works best.

For reeds, consider a separate reed case with built-in humidity control, then give that case its own snug slot inside your clarinet case. This double-layer approach protects reeds from crushing and stabilizes moisture, which can add days or weeks to reed life for busy players.

Safety, Theft Prevention, and Travel Considerations

Interior customization can support safety and theft prevention, especially for players who travel frequently. While locks and outer shells matter most, the interior layout influences how quickly you can check contents, secure valuables, and move through airports or crowded venues without mishaps.

Design your interior so that you can visually confirm all critical parts in a single glance. Each joint, mouthpiece, and reed case should have a clearly defined spot. This makes it easier to notice if a barrel, mouthpiece, or accessory is missing before you leave a rehearsal space or stage.

For air travel, create a layout that allows quick removal of the clarinet for security checks without spilling accessories. Keep loose items in closed pockets or trays with lids. Avoid stacking heavy accessories over the clarinet joints, which can increase damage risk if the case is jostled.

If you carry high-value mouthpieces or barrels, consider a discrete internal compartment with a soft cover flap or zipper. This does not replace external security, but it keeps valuables out of immediate view when you open the case in public spaces or crowded pits.

For backpack-style or double cases, reinforce areas where straps attach by adding foam blocks or stiffeners under the interior lining. This spreads load forces and reduces the chance that a strap anchor will deform the shell and press into the clarinet during long walks or commutes.

Label your case interior with your name and contact information on a small, non-obvious tag. If the case is lost but opened by a venue manager or airline staff, a visible interior label can speed return without advertising ownership details on the outside.

Maintenance & Troubleshooting: Caring for Your Customized Interior

A customized clarinet case interior needs regular maintenance to stay protective and clean. Build a simple routine that matches your playing schedule. This helps you catch wear, foam compression, or moisture problems before they threaten your instrument or accessories.

Monthly routine: Inspect foam and fabric for compression, tears, or loose edges. Gently vacuum the interior with a soft brush attachment to remove dust, lint, and reed chips. Check straps, elastic, and Velcro for loss of tension. Confirm that joints still fit snugly without forcing.

Seasonal routine: Replace or recharge silica gel and other desiccants at each major seasonal change. Wipe fabric surfaces with a slightly damp cloth and a small amount of mild detergent if needed, then allow the case to dry open in a well-ventilated room before storing the clarinet inside.

Hygrometer checks: Test your hygrometer every few months by placing it in a sealed bag with a known humidity source, such as a calibration pack, and comparing readings. Replace batteries as needed. If readings drift significantly, consider replacing the unit.

Yearly inspection: Examine adhesive joints where foam meets the shell and where fabric meets foam. Look for lifting edges, bubbles, or hardened glue. Check lid padding for sagging or contact with keys. Replace worn straps and re-glue or replace any loose foam blocks promptly.

Common troubleshooting issues include rattling, foam compression, mold or mildew, sticky adhesives, and warped lids. Rattling usually means a recess is too large or foam has compressed. Add a thin top layer of foam or re-cut the recess for a closer fit, focusing on supporting wood surfaces, not keys.

If foam compresses severely or stays crushed, switch to a higher-density closed-cell foam for structural support. For mold or mildew, remove the clarinet, clean the interior with a fabric-safe cleaner, dry thoroughly, and improve ventilation and humidity control. Persistent mold may require replacing affected foam or fabric.

Inspiration & Case Interior Examples by Player Type (Student, Orchestral, Travel)

Different clarinetists benefit from different interior layouts. Thinking in terms of player type helps you prioritize what matters most: durability for students, efficiency for orchestral players, and compact security for frequent travelers. Use these examples as starting points for your own design.

Student-focused layout: Emphasize durability and simplicity. Create large, clearly shaped recesses for each joint, with generous foam around the bell and mouthpiece. Add a single, wide accessory well for reed cases, grease, and swabs, plus a mesh lid pocket for music pencils and small items.

Orchestral or pit player layout: Prioritize fast changes and multiple setups. Include two or three mouthpiece slots, a dedicated barrel slot, and a secure space for a backup clarinet or A/B-flat pair if the case allows. Add labeled compartments for different reed strengths and tools for quick adjustments.

Travel and touring layout: Focus on compactness and security. Use tight-fitting recesses with extra lid padding, and keep accessories in covered trays or zippered pouches. Integrate a digital hygrometer and desiccant compartment, and consider a hidden pocket for documents or small valuables.

Teachers and small repair shops might build hybrid interiors. For example, a case used for school visits could hold one main clarinet, a loaner mouthpiece set, basic repair tools, and demonstration reeds, all in clearly separated sections. This reduces the need to carry multiple bags and speeds up clinic sessions.

Whatever your player type, sketch your typical day or week and list what you actually carry. Then design your interior around that list, not around a generic factory layout. This mindset leads to a case that truly supports your playing life instead of fighting it.

Cost, Where to Buy, and When to Hire a Professional

Clarinet case interior customization can be surprisingly affordable, especially if you already own basic tools. Costs vary based on foam type, fabric quality, and whether you hire a professional. Planning a budget ahead of time helps you choose materials that match your goals and playing schedule.

For DIY projects, expect to spend roughly 30 to 100 USD on foam, fabric, adhesives, and small hardware. Higher-density EVA or HDPE foam and marine-grade fabrics sit at the upper end of that range but offer better durability. Digital hygrometers and humidity packs add another 15 to 40 USD depending on brand and features.

You can buy materials from upholstery suppliers, marine and automotive fabric stores, craft chains, and online foam specialists. When ordering foam, check density and cell type, and ask for sample swatches if possible. For fabrics, choose materials rated for abrasion resistance and colorfastness to avoid dye transfer to your clarinet.

Hiring a professional case or instrument technician is wise if you have a high-value clarinet, a complex double case, or limited time. Professional customization often ranges from about 150 to 400 USD or more, depending on complexity, materials, and region. This usually includes precise measurement, CNC or hand-cut foam, and clean fabric work.

Consider professional help if your case shell is warped, if you need structural repairs, or if you are unsure how to protect unusual keywork, such as on historical or low clarinets. A skilled technician can also advise on humidity strategies that match your climate and instrument wood.

Before committing, ask for photos of past projects, material details, and an estimate that includes both labor and parts. A well-done custom interior can last many years, so it is often worth investing more upfront for higher-quality foam and fabric.

Conclusion: Next Steps, Checklist, and Downloadable Templates

Clarinet case interior customization gives you control over protection, organization, and climate around your instrument. By understanding clarinet anatomy, choosing appropriate foams and fabrics, and planning a clear layout, you can create an interior that supports your playing goals and protects your investment every day.

Before you start cutting foam, walk through a simple checklist. Confirm your case shell is structurally sound, list all items you want to carry, measure everything carefully, and decide which tasks you feel comfortable doing yourself. Leave structural repairs or complex double-case projects to experienced technicians if needed.

A practical next step is to create full-size paper templates of your clarinet joints and accessories. Tape them into your empty case and rearrange until the layout feels natural. This low-cost step often reveals better arrangements and avoids wasted foam or fabric later.

Many players find it helpful to keep a one-page reference with their case: target humidity range, desiccant replacement dates, and a quick visual of where each item belongs. Over time, this turns your customized interior into a consistent routine that supports reliable practice, performance, and travel.

Key Takeaways

- Design your interior around clarinet anatomy, supporting wood surfaces while keeping keys and bridge mechanisms free from pressure.

- Use high-density closed-cell foams, durable fabrics, and secure fittings to balance shock protection, humidity control, and long-term stability.

- Plan organization systems so every joint and accessory has a clear home, improving setup speed, reed life, and overall confidence on stage and on the road.

FAQ

What is clarinet case interior customization?

Clarinet case interior customization is the process of redesigning and rebuilding the inside of a clarinet case so it fits your instrument and accessories precisely. It usually involves cutting foam, adding fabric, and integrating pockets or straps to improve protection, organization, and humidity control.

What materials are best for cushioning a clarinet inside a case?

The best cushioning materials are high-density closed-cell foams such as EVA and polyethylene, often layered with a thin, softer top foam like cross-linked polyethylene or neoprene. These foams absorb shock, resist long-term compression, and can be covered with durable fabrics like marine-grade carpet or velour.

How do I control humidity inside a clarinet case?

Control humidity by adding a small digital hygrometer, using silica gel or two-way humidity control packs, and designing a ventilated compartment for them. Aim for a relative humidity range around 40 to 60 percent for most wooden clarinets, and adjust desiccant quantity as seasons and local climate change.

Can I customize my case interior without professional help?

Yes, many clarinetists and small repair shops successfully customize interiors with basic tools, careful measurements, and quality materials. Start with paper templates and simple foam inserts. If you have a very valuable instrument or complex case, consider consulting a professional for design or final fitting.

How much does a professional case interior customization typically cost?

Professional clarinet case interior customization often costs between about 150 and 400 USD, depending on case size, material choices, and complexity. This usually includes measuring, cutting or machining foam, applying fabric, and installing straps or pockets. High-end touring or double cases may cost more.

Will customizing my case interior affect my instrument warranty or resale value?

Customizing the interior of a separate case usually does not affect the clarinet's warranty, since you are not altering the instrument itself. However, modifying an original factory case might affect its resale value as a collectible. Keep the work reversible when possible and avoid structural changes to the shell.