How to replace a clarinet ligature screw: Lay out a small screwdriver, replacement screw, and a soft cloth. Remove the ligature, clean and inspect it, then thread in the new screw by hand before lightly tightening with the screwdriver. Reattach the ligature, adjust tension until the reed vibrates freely, then test play and fine tune.

What is a ligature and what does a ligature screw do?

A ligature is the clamp that holds your clarinet reed against the mouthpiece. The ligature screw is the small threaded fastener that tightens or loosens this clamp. By turning the screw, you change how firmly the ligature presses on the reed, which directly affects vibration, response, tone color, and intonation stability.

On a typical Bb clarinet mouthpiece, the ligature wraps around the reed and mouthpiece body. One or two posts on the ligature are connected by the screw. As you turn the screw clockwise, the posts draw together, increasing pressure. Turn it counterclockwise and the ligature relaxes, allowing the reed to vibrate more freely.

Most student and intermediate ligatures use a single screw at the front or side. Advanced models may use two screws for more even pressure. Regardless of design, the screw is the control point for pressure. If it fails, strips, or goes missing, the ligature cannot hold the reed securely and performance stops immediately.

Historically, early clarinets used simple string or cord instead of a metal ligature. As metal ligatures evolved in the 19th and 20th centuries, small screws replaced knots, giving players faster adjustments and more consistent pressure. Many surviving historical clarinets, including some associated with the Martin Freres name, show this transition from cord to screw-based ligatures.

How ligature screw tension affects sound (pressure -> tone -> intonation)

Ligature screw tension changes how much of the reed can vibrate. More pressure limits vibration and can brighten or thin the sound. Less pressure frees the reed but can reduce focus. The goal is a balanced tension where the reed speaks easily, the tone is centered, and intonation stays stable across the range.

Think of the screw as a fine-tuning control for reed freedom. Small turns make noticeable differences. A quarter turn tighter or looser can change articulation clarity, dynamic control, and how easily notes start, especially in the throat and clarion registers. Intermediate players often overlook this and blame the reed or mouthpiece instead.

| Pressure level | Sound & response | Intonation effect |

|---|---|---|

| Too high (over-tight screw) | Bright, thin, sometimes harsh. Reed feels stiff, attacks feel delayed, soft dynamics are hard. | Notes may go sharp, especially in the upper register. Pitch feels inflexible. |

| Too low (under-tight screw) | Flabby, unfocused tone. Response is inconsistent, reed may buzz or rattle. | Pitch can sag flat, especially in low register. Slurs feel unstable. |

| Just right (balanced tension) | Warm, centered tone with clear core. Easy response at all dynamics. | Pitch locks in easily with tuner, stable across registers. |

To find your ideal tension, start from barely tight enough to hold the reed, then slowly tighten in tiny increments while playing long tones. Listen for the point where the tone gains focus without losing warmth. Use a tuner or tuning app to see how pitch changes as you adjust screw pressure.

During performance, check tension quickly by gently nudging the reed with a fingernail. It should not slide, but it should not feel locked in a vise. Over time, you will develop a feel for the right resistance that gives you reliable response and stable intonation in rehearsal and on stage.

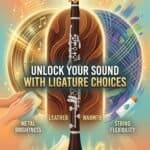

Common ligature screw types and materials

Ligature screws vary by thread size, length, head shape, and material. Knowing these details helps you choose compatible replacements. Most clarinet ligatures use metric threads, but some older or specialty models use unique sizes. Always match thread size and pitch to avoid cross-threading or damage.

The most common screw head styles are knurled finger screws and small screwdriver heads. Knurled screws have a textured grip so you can adjust tension with your fingers. Some band ligatures use flat-head or Phillips-head screws that are meant to stay installed and rarely removed, relying on a screwdriver for occasional adjustment or replacement.

Materials include brass, nickel-plated brass, stainless steel, and sometimes plastic for student models. Brass and nickel-plated screws are standard on many metal ligatures. Stainless steel offers higher strength and corrosion resistance. Plastic screws are light and inexpensive but more prone to stripping if overtightened.

Metal ligatures with metal screws tend to give a more focused, projecting sound. Fabric or leather ligatures often use metal screws but flexible bands, giving a warmer tone. The screw itself has less tonal impact than the ligature body and reed, but its ability to hold consistent tension is critical for repeatable sound.

Some vintage ligatures, including those found on historical Martin Freres clarinets, use unique screw designs that are not compatible with modern parts. In those cases, a repair technician may fabricate a custom screw or recommend a period-appropriate replacement ligature to preserve both playability and historical character.

Tools and preparation you need (workshop checklist)

Replacing a ligature screw is a simple workshop task if you prepare properly. Set up a clean, well lit workspace so you do not lose tiny parts. Use a tray or cloth to catch small screws. Keep your clarinet body in its case while you work on the mouthpiece, reed, and ligature.

Here is a practical checklist for clarinet ligature screw work:

- Small Phillips or flat-head screwdriver (to match your screw head)

- Replacement ligature screw(s) that match thread size and length

- Soft, lint free cloth for the mouthpiece and ligature

- Tuning fork, pitch pipe, or tuner app for post-replacement testing

- Optional: magnifying glass to inspect threads and posts

- Optional: low strength, removable threadlocker for chronic loosening

Before you begin, wash and dry your hands to avoid transferring oils to the reed or mouthpiece. Place the mouthpiece on a stable surface, not on the clarinet. Have a small container ready to hold the old screw and any washers or caps so nothing rolls away during the procedure.

Step-by-step ligature screw replacement procedure

This step-by-step method keeps the process organized and repeatable. Follow each step in order so you do not miss important checks. The same procedure works for most Bb, A, and bass clarinet ligatures that use standard screws.

Step 1: Remove the ligature and reed

Carefully loosen the ligature screw until the ligature slides off the mouthpiece. Remove the reed and place it on a clean reed case or glass surface, tip up. Do not set the reed directly on your workbench where it can chip or warp.

Step 2: Clean the mouthpiece

Use a soft, slightly damp cloth to wipe the mouthpiece table, rails, and side walls. Remove dried reed residue where the reed sits. Avoid harsh cleaners that can damage ebonite or plastic. A clean table helps the reed seal properly when you reinstall the ligature and new screw.

Step 3: Inspect the ligature and posts

Look closely at the ligature, especially the screw posts. Check for cracks, bends, or warping. Inspect the threaded holes where the screw fits. If the posts are badly bent or cracked, replacing only the screw will not solve the problem. In that case, plan to replace the entire ligature.

Step 4: Install the new ligature screw

Align the new screw with the threaded post and start turning it gently by hand. It should turn smoothly for several full rotations. If you feel resistance or grinding, stop immediately and realign. Once the screw is mostly seated, use the screwdriver for only a final light snugging, not heavy torque.

Step 5: Reattach the ligature and reed

Place the reed on the mouthpiece table, aligning the tip with the mouthpiece tip. Slide the ligature over the reed carefully, avoiding contact with the reed tip. Center the ligature over the heart of the reed. Begin tightening the screw until the ligature just holds the reed in place without sliding.

Step 6: Adjust ligature screw tension

With the reed secured, make small adjustments to screw tension. Use finger pressure if you have a knurled screw, or a screwdriver with very light touch if required. Aim for a setting where the reed does not move under gentle pressure but still feels resilient, not clamped flat against the table.

Step 7: Test play and fine tune

Assemble the clarinet and play long tones in the low, throat, and clarion registers. Listen for response, tone focus, and stability. Use a tuning fork, pitch pipe, or tuner app to check pitch on concert F, G, and B flat. Make tiny screw adjustments, no more than 1/8 turn at a time, then retest.

Maintenance best practices and storage tips

Good ligature screw maintenance prevents sudden failures during rehearsal or performance. Treat the screw as a precision part, not a disposable accessory. Regular checks and gentle handling extend its life and protect the ligature posts from damage or stripping.

Once a week, remove the ligature and wipe the screw threads with a dry cloth to remove dust and dried moisture. If you notice greenish corrosion on brass parts or rust on steel, clean gently and consider replacement. Avoid oiling the screw unless a technician recommends it, since excess oil can migrate to the reed.

When storing your clarinet, remove the reed and ligature from the mouthpiece. Store the ligature in a dedicated compartment or small pouch so the screw is not crushed or bent by other items in the case. Do not leave the ligature tightened on an empty mouthpiece for long periods, as this can stress the posts and threads.

Keep at least one spare ligature screw in your case, ideally in a small labeled container. Many players also carry a complete backup ligature. That way, if a screw fails or disappears on stage, you can swap quickly without interrupting the performance more than a few seconds.

Troubleshooting common ligature screw problems

Even with careful use, ligature screws can develop issues like stripping, cross-threading, or sudden loosening. Recognizing the symptoms early helps you avoid damage to the ligature or mouthpiece and keeps your clarinet ready for performance.

Stripped threads

Stripped threads feel rough or loose, and the screw may spin without tightening. Inspect both the screw and the ligature post. If the screw threads look flattened or shiny, replace the screw. If the post threads are damaged, the ligature itself usually needs replacement or professional repair.

Misaligned or bent posts

If the posts do not line up, the screw will bind or cross-thread. Look from above and from the side to see if the posts lean. Minor bends can sometimes be corrected by a skilled technician, but forcing the screw through misaligned posts almost always makes the problem worse.

Cross-threading

Cross-threading happens when the screw starts at an angle and cuts a new, wrong path into the post. You may feel sudden resistance or hear a scraping sound. Stop immediately, back the screw out, and realign. If the screw will not start smoothly by hand, do not use a tool to force it.

Loose screw during performance

If the screw keeps backing out while you play, first check that the threads are clean and undamaged. As a temporary fix, you can apply a tiny amount of low strength, removable threadlocker to the screw, let it set fully, and then reinstall. Use only non permanent products and very small amounts to avoid gluing the screw in place.

For emergencies, if a screw falls out and you have no spare, a rubber band or small piece of string can hold the reed long enough to finish a rehearsal. This is not ideal for tone or intonation, but it can save the day. Replace or repair the ligature as soon as possible afterward.

Key takeaways

- The ligature screw controls reed pressure, which shapes tone, response, and intonation more than many players realize.

- Balanced tension comes from light, even pressure: the reed should not slide, but it should still vibrate freely and speak easily.

- A simple 7 step routine keeps ligature screw replacement safe: remove, clean, inspect, install, reattach, adjust, and test play.

- Regular inspection, gentle tightening, and carrying spare screws or a backup ligature prevent performance stopping failures.

FAQ – quick answers and quick fixes

What is ligature screw?

A ligature screw is the small threaded fastener that tightens the clarinet ligature around the reed and mouthpiece. Turning the screw changes how firmly the ligature presses on the reed, which directly affects how the reed vibrates, how easily notes start, and how stable your tone and intonation feel.

How does ligature screw tension change my clarinet sound?

Tighter ligature screw tension increases pressure on the reed, often giving a brighter, more focused sound but risking harshness and sharp pitch if overdone. Looser tension frees the reed, which can sound warmer but less centered. The best setting gives a clear, warm tone with easy response and stable pitch.

What tools do I need to replace a ligature screw?

You typically need a small Phillips or flat-head screwdriver that matches your screw, a correctly sized replacement screw, and a soft cloth for cleaning the mouthpiece and ligature. A tuner, tuning fork, or pitch pipe helps you test intonation after replacement. A small container keeps tiny parts from getting lost.

How do I replace a ligature screw step-by-step?

Remove the ligature and reed, then clean the mouthpiece. Inspect the ligature posts for damage. Thread the new screw into the post by hand, then lightly snug it with a screwdriver. Reattach the ligature over the reed, adjust tension until the reed is secure, and test play while making small tension adjustments.

What should I do if the screw strips or cross-threads?

If the screw strips, replace it and inspect the ligature post. If the post threads are damaged or the screw cross-threads repeatedly, stop using that ligature to avoid further damage. Do not force the screw. Consult a repair technician or replace the ligature, and keep a spare ligature or screw in your case for emergencies.